Some surface testing systems detect specific pathogens, and others are designed for more general purposes. When testing cleanliness, most swabs test one of two things: phosphates or proteins. More specifically, some swabbing systems detect ATP (Adenosine triphosphate) and others detect protein (either specific allergenic protein, or general protein). The systems address entirely different needs. So how do you know when to use ATP swabs, general protein swabs, or allergen-specific swabs in your facility?

Protein Swabbing

Protein is found in most foods. Foods that are high in protein, including nuts, shellfish, soy, and milk appear on the list of major allergens. Interestingly enough, most fruits and vegetables contain a very minimal amount of protein — although these foods can still trigger allergic reactions in some people!

Since food proteins are generally what trigger an allergic reaction, verifying that proteins have been removed from the work environment is vitally important. Can you prove that working surfaces are (largely) free from protein? If so, you can feel reasonably confident that the surfaces will not contaminate your products with traces of allergens.

General Protein surface testing

An effective and widely-used method, general protein testing checks for the presence of any protein on a surface. These surface tests do not differentiate between protein from nuts, meats, dairy, etc. – any protein will trigger a reaction. General protein swabs are less sensitive than allergen-specific tests, but they are also much less expensive. This makes them a good addition to a food safety program, especially when it comes to verifying that cleaning has taken place.

An effective and widely-used method, general protein testing checks for the presence of any protein on a surface. These surface tests do not differentiate between protein from nuts, meats, dairy, etc. – any protein will trigger a reaction. General protein swabs are less sensitive than allergen-specific tests, but they are also much less expensive. This makes them a good addition to a food safety program, especially when it comes to verifying that cleaning has taken place.

Surface testing for general protein involves swabbing an area and then incubating the sample before reading the result. Some methods don’t require an incubation period, but they are less sensitive and not suitable for use with allergen cleaning. All methods of rapid protein surface testing will cause the sample to change colors when mixed with the reagent or through incubation.

While there are many brands of general protein swabs, we are pleased to carry Hygiena’s AllerSnap™ protein tests. AllerSnap uses the biuret method (see more, below); it is safe, quick, easy and effective.

The biuret method is a colorimetric technique specific for proteins and peptides. Copper salts in alkaline solution form a purple complex with substances containing two or more peptide bonds. The absorbance produced is proportional to the number of peptide bonds that are reacting and therefore to the number of protein molecules present in the reaction system.

Read the article on Science Direct

Protein swabs alone should not be used for allergen control since they only work on surfaces and only detect protein molecules with no differentiation. In other words, protein tests cannot tell the difference between protein from an allergen like peanut and any other protein. They are also less sensitive than tests for specific allergens. In situations where no test kit is available to screen for a particular allergen, verification with a kit like AllerSnap can be useful.

Advantages of protein swab tests:

- Detects protein from a wide range of allergens, including allergens for which there is no specific rapid test

- Quick results – 5 to 30 minutes depending incubation

- Cost effective to allow for collecting multiple data points

- Easy to use and interpret

Specific Allergen product and surface testing

Unlike AllerSnap or other general protein swabs, specific allergen tests contain antibodies designed to react to very small amounts of very specific allergen proteins. In other words, a kit designed to detect peanut will “ignore” protein from milk or soy or chicken. They are almost always more sensitive than general allergen swabs. This makes them the superior choice for higher risk situations and also for program validation.

Fun fact! It is a good idea to validate your cleaning program at least once a year with specific-allergen tests. Validation is the means of proving that your cleaning program does in fact work, when it is done properly. Additional validation is warranted when there are changes to your ingredients, processes, environment, or team.

Rapid /On-Site testing for specific allergens

There are also a variety of on-site rapid lateral flow devices for detecting specific allergens. The benefits of an LFD are many. Like ELISAs, they are more sensitive and more specific than the general protein swabs. They can also detect allergenic material in food samples, rinsewater samples, and surface samples. When you are trying to prove that your cleaning program works, specific allergen test kits are heavily indicated. Kits like AlerTox Sticks and GlutenTox are also advisable for high-stakes allergen cleans, and monitoring incoming ingredients, rinsewater, and finished product. The process of getting set up to start testing is as simple as ordering a test kit and blocking off 15 minutes on your schedule.

Advantages of allergen-specific LFD tests

- Most sensitive and specific rapid option

- Can be used on rinsewater and product in addition to surfaces

- Quick results – appx 15 minutes

- No equipment required

- Cost effective compared to third party ELISA

- Easy to use and interpret

ELISA testing for specific allergens

There are ELISA tests for specific allergens, which are frequently used by food safety labs. ELISA tests can detect allergens in products as well as in surface swabs. The biggest benefit to an ELISA test is the quantitative answer. When it comes to testing products, it’s informative to know whether you have a contamination issue of 15 or 1500 ppm. Surface testing results are qualitative: the test either did or did not detect allergen in question.

PCR testing for specific allergens

Sometimes, a lab will use a PCR test to look for a specific allergen. PCR tests are less common and more time-consuming than protein-specific LFDs and ELISAs. However, because PCR tests look for DNA and not for protein, there are cases where they are the best or only option. Celery is a prime example: since there is so little protein in celery, it is very hard to create an ELISA or LFD that can detect this allergen. However, a PCR test can easily look for celery DNA.

ATP Testing

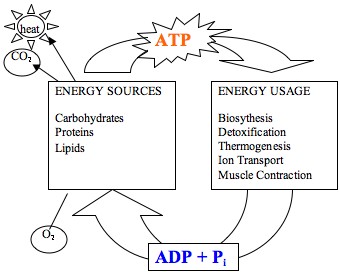

ATP (adenosine tri phosphate) is the principal molecule for storing and transferring energy in all living cells. Adenosine triphosphate and its components, AMP and ADP (mono and di phosphate) are constantly interconverted as they participate in biological reactions.1 They are present in all living creatures, from bacteria right on up to humans.

ATP (adenosine tri phosphate) is the principal molecule for storing and transferring energy in all living cells. Adenosine triphosphate and its components, AMP and ADP (mono and di phosphate) are constantly interconverted as they participate in biological reactions.1 They are present in all living creatures, from bacteria right on up to humans.

Note! Viruses do not produce ATP.

Much like how general protein swabs cannot distinguish between protein from various sources, ATP tests cannot distinguish between bacteria, yeast, mold or food residue. By demonstrating that the amount of ATP (measured in RLU) has dropped sufficiently following sanitation, a facility can ensure that the risk of products being contaminated by microbial organisms has been minimized.

1 shortened Scitable definition of ATP

ATP surface testing

Surface tests for ATP are rapid and easy to conduct, but do require a special reading device called a luminometer. Each brand of testing swabs offers its own corresponding device. To run a test, an area is swabbed and exposed to a reagent that contains the enzyme luciferase. When ATP is present, it will react with the enzyme, and will emit light that can be detected by a luminometer. The luminometer measures the amount of ATP that is present in RLUs (relative light units), which corresponds to the amount of biological energy present in the sample.

Fun fact! The reaction that produces the light is based on the enzyme luciferase, which is naturally occurring in fireflies and some marine animals!

ATP testing can be a very effective tool in monitoring for pathogens, yeasts, molds, and other microbiological cleanliness concerns. If ATP isn’t present after cleaning, then there isn’t the opportunity for microbial growth that could lead to major issues down the line.

Since ATP tests are portable, and can be conducted onsite, they can provide a quick analysis of cleaned surfaces and a verification of cleaning procedures. They are also used outside of the food industry anywhere that cleanliness is a concern.

That being said: with very few exceptions, ATP swabbing is not a suitable method for allergen management. ATP is not protein and protein is not ATP. While there are correlations, they are not strong or consistent enough to base an allergen cleaning plan on. Instead, testing for proteins and testing for ATP are complimentary parts of a strong, holistic safety plan.

In Summary

Whether your facility is dedicated to producing gluten and allergen free products, or includes lines shared with allergen-containing recipes, identifying hazard points is your first step in managing the risk of cross-contact. Where is contamination most likely to occur? Which of your ingredients are highest-risk, and which steps in your manufacturing process are most likely to involve inadvertent exposure to gluten or allergens? A well thought out quality control plan takes experience and expertise to develop and to implement, but will result in benefits to your final product and ultimately the consumer.