Should commercial kitchens use protein swabs for food safety?

Ensuring food safety in food service is vastly different than in a manufacturing environment. While a food manufacturing facility will make one item at a time per line it operates, cafeteria and commissary staff must make dozens of different foods daily and on short notice. Each dish comes with its own risks and hazards, from allergen cross-contact to unsafe storage temperatures.

Luckily, one of the manufacturing sector’s most common, quick, and inexpensive tools can be used in commercial kitchens as well: general protein swabs. Protein swabs are a handy, onsite way to verify your work surfaces, utensils and equipment are clean. Read on to learn where protein swabs can be useful in commercial kitchens.

What is a protein swab?

What is a protein swab?

Testing for protein involves running a swab across a surface and then soaking it in the test solution. The amount of protein left on a surface will correspond to a specific color in the liquid — often purple or blue. Because protein is found in almost every kind of food, it’s a good indicator of an unclean surface.

Monitoring surface cleanliness

Is everybody on your team following your SOP on cleaning prep surfaces? Detecting protein residues with a protein swab can indicate that a surface has not been properly cleaned. Regular use of protein swabs can help kitchen staff ensure that surfaces are clean and sanitary, reducing the risk of food-borne illness.

If in the course of your day-to-day, any test fails, then you know that the area must be re-cleaned. Failure can also indicate an area that may need to be addressed for more frequent cleaning, or additional team training.

Verifying allergen cleaning

Almost any commercial kitchen will have to manage allergens for food-allergic diners. Protein swabs can add an extra level of verification that surfaces in an allergen-free prep section are indeed allergen free. Protein swabs are fast, and easy to use and interpret. This extra layer of verification can help prevent cross-contact and reduce the risk of allergic reactions. It’s important to note that ANY protein will trigger a positive result — these tests cannot tell the difference between peanut, wheat, chicken, chickpea, or anything else.

If you need to check for a specific allergen, we recommend AlerTox Sticks which are offered for a variety of common food allergens.

Quality control

Vegan or vegetarian preparation can also benefit from using protein swabs for quality control. The last thing you want is to accidentally cross-contact meat bearing surfaces with your vegetable-based dishes. The same thing applies for the preparation of different plates that contain beef, pork, poultry or ham. If the surfaces test with no protein residue, accidental cross-contact is minimized.

More than just countertops

Any type of surface can be tested for protein. Your pots and colanders for boiling pasta? Check them! The tabletops where people eat? Pans for finishing off individual dishes? Cambro containers being repurposed for storing different foods? Swab away! Protein swabs will verify that your team did in fact perform the day’s cleaning plan, providing an extra layer of assurance that your team’s performance is top notch.

Easy to use

Any team member can be easily trained to run protein swab tests. They are easy to use, and give results in minutes. They can serve as a a verification of your SOP and team training, keeping everyone aware of risks and staying on top of your cleaning procedures.

How do protein residue tests work?

How do protein residue tests work?

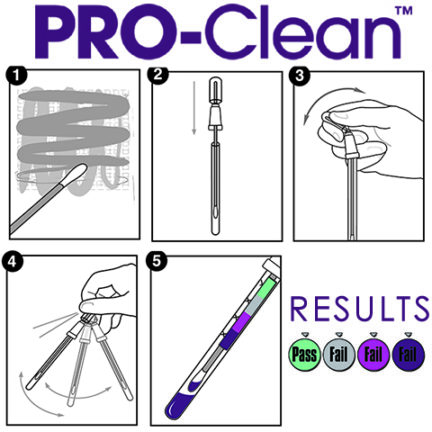

PRO-Clean™ is our suggestion for food service facilities. The test is easy: swab the testing area and snap the bulb to release a reagent, wait, then match the color to the chart: green means clean and purple means re-clean.

The PRO-Clean kits use the biuret method, a colorimetric technique specific for proteins and peptides. Copper salts in alkaline solution form a purple complex with substances containing two or more peptide bonds. The absorbance produced is proportional to the number of peptide bonds that are reacting and therefore to the number of protein molecules present in the reaction system. If you’re curious to learn more about this technology, you can learn more here: ~Read the article on Science Direct

Want to learn more?

Click below to learn more about the product, or contact us with questions at your convenience.